Chassis

BOGE Rubber & Plastics is the development partner for individual design solutions tailored to the customer's needs at competitive prices. The economical lightweight design of each rubber mount is achieved by consistently combining BOGE's longstanding expertise in elastomer and plastics across all locations.

In teamwork with our customers and suppliers, we develop comprehensive elastokinematic chassis solutions for the brand-specific driving experience.

We also offer specific solutions for high axle loads for battery electric vehicles and plug-in hybrid electric vehicles and develop Subframe Mount with axial damping to reduce disturbing vibrations and noise in the passenger compartment.

-

Isolates micro-vibrations and optimizes vertical damping

-

Supports stiffness of the front end

-

Integrates functions in a very small space

-

High load transmission for elastokinematically defined maneuverability

-

Optimized for weight and cost

-

Supports reduction of roll motions

-

Defined transmission of the vertical axle forces

-

Integrates function and lightweight design

-

Increasing comfort by decoupling chassis and car body

-

Optimized damping properties increase comfort

-

Optimizes system vibrations of axle and powertrain

-

Switchable version possible

-

Transmits high loads in minimum space

-

High radial stiffness with lowest possible torsion rate

-

Optimizes the relation of driving dynamics and comfort

-

Crucial for the elastokinematic performance of the axle

-

Integrates functions by optimal connection of the axle

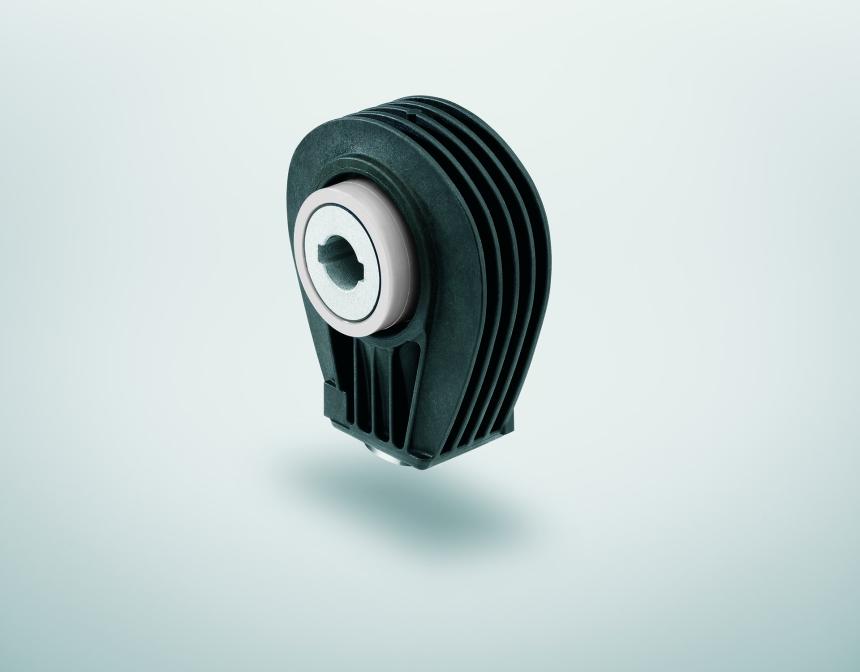

Powertrain

Due to the global requirement for saving CO2, the market increasingly offers different powertrains in one vehicle platform. Many current concepts include engine downsizing (e.g. fewer cylinders or omission of balance shafts), engines with cylinder shut-off, hybrid engines or electric engines. These modern, very different drive concepts in combination with weight-reduced vehicle structures generate stronger vibration excitations and require existing NVH concepts to be developed further.

With switchable and active mounts with hydraulic damping which automatically adapt their functions to the current driving situation, the customized solutions from BOGE Rubber & Plastics provide an essential contribution to improving the comfort of vehicle passengers.

-

Optimizes idle behavior

-

Maximizes vibration damping while driving

-

Compact design

-

Lightweight and robust

-

Combination of different materials

-

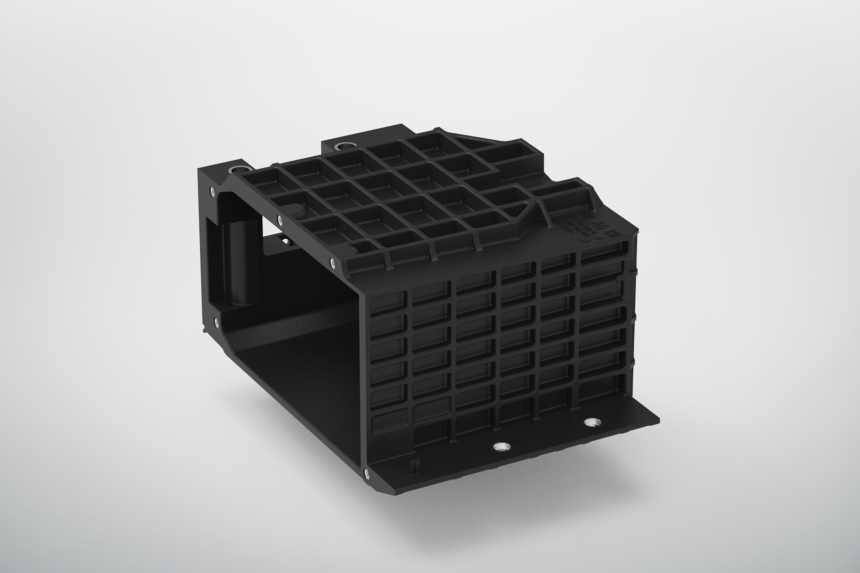

Supplied as modules

-

Integration of product and functions

-

Enhanced safety and comfort

-

Integration of rubber suspension mounts

-

High component stiffness using innovative plastic-aluminum hybrid design

-

Optimized NVH and crash

-

High functionality in a small space

-

Isolates vibrations in the powertrain

-

More comfort – best driving dynamics

-

Isolates vibrations in the powertrain

-

Keeps unwanted noise and roughness away from the driver

-

Ensures torque support

-

Weight reduction while highly robust

-

Optimized noise insulation

-

More comfort through excellent driving dynamics

-

Reduced package space requirements

-

Long service life

Resting pole in the Powertrain

Active engine mounts optimally dampen and isolate the oscillations, noise and vibrations generated by the car engine in every operating state of the combustion engine. This noticeably increases the comfort of the vehicle occupants. Apart from the positive effect on the occupants, the active engine mount plays an important role in downsized engines and vehicles with electronic cylinder deactivation, which constantly change their vibration behavior. It makes a significant contribution to making these innovations convenient and marketable.

Plastics solutions for engine compartment applications

As a system supplier, we develop, design and produce complex, high-quality plastic products and modular systems for our customers worldwide. Our in-house team of developers create hand in hand with our own tool manufacturing plastic components of the highest quality and on schedule. Innovative new materials with a focus on ultra-lightweight design using continuous glass fiber technologies round off our range of services.

-

Design cover

-

Battery cover

-

Engine oil pan

-

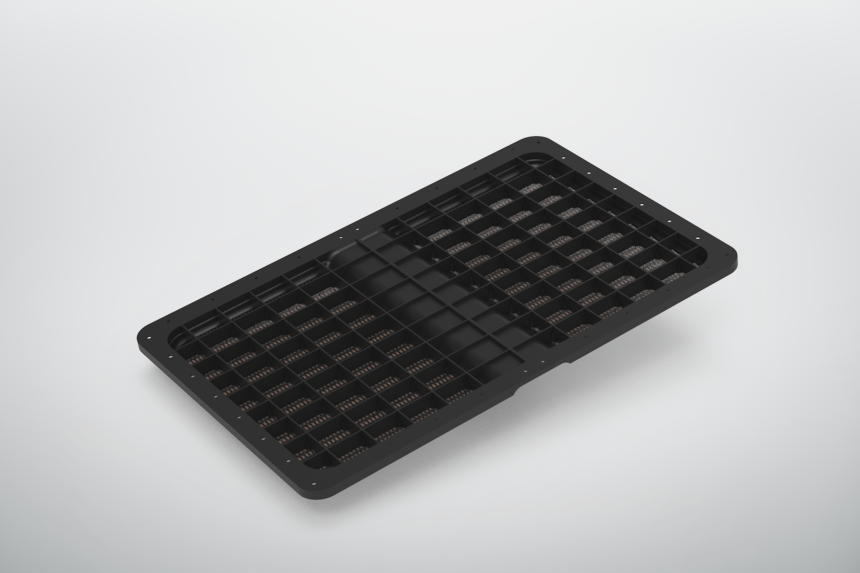

Suction filter

-

Transmission oil pan

-

Toothed belt cover

-

Chain guide/Guide rail

-

Cylinder-head cover

-

Battery tray

-

Brackets

-

Air intake tube

-

Charge air ducts

-

Intake manifolds

-

Pressure pipes

-

Air intake systems

-

Suction jet pumps

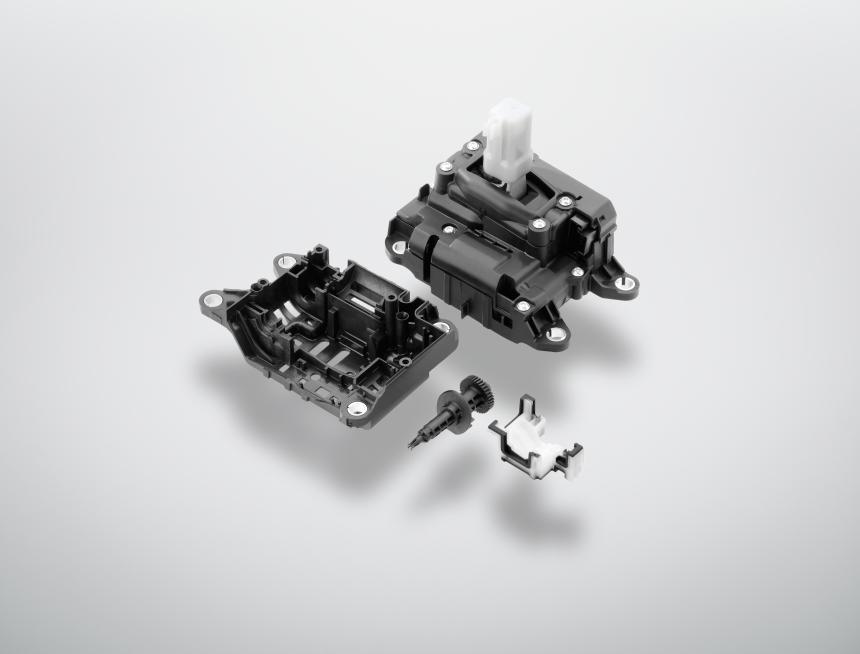

Actuating systems

Lightweight design saves CO2 and makes vehicles more agile and economical. As a “Full Service Supplier”, BOGE Rubber & Plastics can provide this lightweight concept. As a competent developing partner, we support customers in the automotive industry as well as in other industries in all aspects of plastic injection molding, right from the initial concept to serial production.

The freedom when designing with plastics enables the excellent integration of functions and, at the same time, reduces the number of components. In addition, plastics are a very environmentally friendly material, which can be completely recycled.

-

Multifunctional design

-

Significant weight reduction through all-plastic brake pedal with continuous fiber

polyamide rib structure -

Integration options for autonomous driving

-

Innovative precision injection molding using two-component and three-component technology

-

High manufacturing precision

-

Weight optimization

Electromobility

Mobility of the future - a topic that moves the entire automotive industry. BOGE Rubber & Plastics meets the increasing demands.

The higher frequencies in electric vehicles require expert knowledge. New NVH (noise, vibration, harshness) systems for electric powertrain concepts with new, innovative products underline our technological leadership. At the same time, we achieve a reduction in emissions and weight through optimized designs and materials.

We are THE partner for high-quality and durable products that minimize vibrations that occur when cornering, braking or on uneven roads and offer optimal vibration damping and noise insulation as well as more stability, safety and driving comfort on the roads.

-

Air intake manifold

-

Expansion tank (oil/cooling water circuit)

-

Cooling water connection

-

Pedal modules

-

Underbody shield

-

Acoustic components

-

Contact bridges

-

Airbag housings

-

Oil filter

-

Oil drip pan

-

Pressure control valves

-

Functional components for transmissions

-

Engine mount

-

Battery protection

-

Powertrain suspension mount

-

Underride guard